MTBE甲基叔丁基醚纯度测定专用毛细管柱,室内空气,焦炉煤气,炼厂气,天然气,变压器油,多氯联苯,植物油,6号溶剂残留,顶空进样器,乙酸乙酯,芝麻香白酒,3-甲硫基丙醇

MTBE甲基叔丁基醚纯度测定专用毛细管柱

在石油化工行业中,大型化、规模化的石化装置在不断地建设和发展,副产物的利用率也在提高,一种汽油添加剂甲基叔丁基醚(MTBE)就是碳四抽提的副产物异丁烯和甲醉通过S型强酸型阳离子树脂催化剂生产出来的,随着石化和汽车工业的发展,MTBE的市场需求逐年增加。

关于MTBE中甲醇的测定,通常采用聚聚硅氧烷固定相,即使150m的柱长,也不能完全放开甲醇和轻烃,无法准确定量。此外也有采用二维/多维色谱法或者中心切割法,操作复杂,设备成本高,一般企业很难配置,根本无法普及。

滕州市浩瀚色谱仪器技术服务有限公司,,,,,色谱工程研究所,分析与测试中心,3个科研单位,研发出《MTBE甲基叔丁基醚纯度测定专用毛细管柱》,重复性好,准确度高,其相对标准偏差小于3%,各组分相对误差小于±1%,能够满足MTBE装置控制分析以及成品MTBE分析.该法可用于工业用甲基叔丁基醚(MTBE)纯度及烃类杂质含量(大于0.005%)的测定。

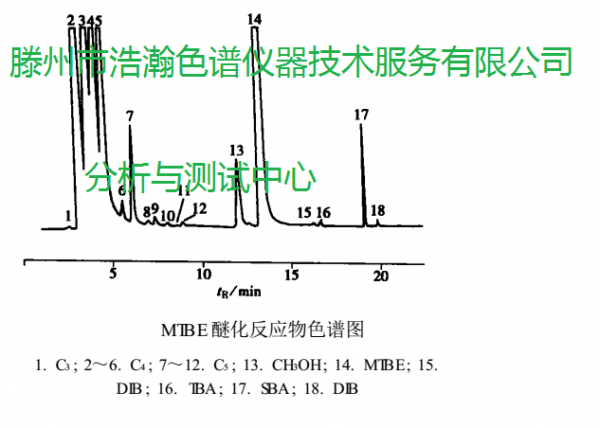

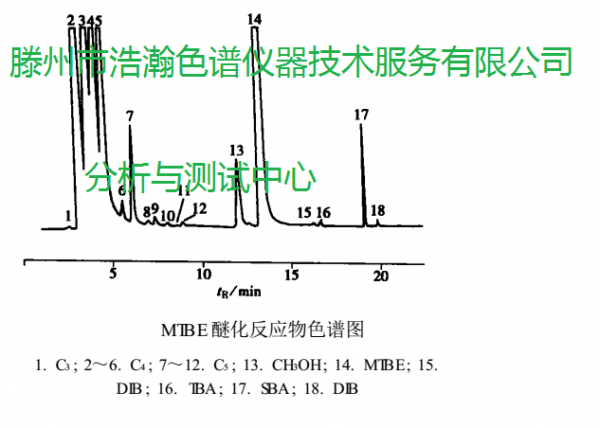

MTBE甲基叔丁基醚纯度测定专用毛细管柱测定谱图:

MTBE special capillary column for purity determination of methyl tert-butyl ether

In the petrochemical industry, large-scale and large-scale petrochemical plants are constantly being constructed and developed, and the utilization rate of by-products is also increasing. A gasoline additive, methyl tert-butyl ether (MTBE), is a by-product of C4 extraction. The products isobutylene and methyl drunk are produced through S-type strong acid cationic resin catalyst. With the development of petrochemical and automobile industries, the market demand for MTBE is increasing year by year.

Regarding the determination of methanol in MTBE, polysiloxane stationary phases are usually used. Even with a column length of 150 m, methanol and light hydrocarbons cannot be completely released and cannot be accurately quantified. In addition, there are also two-dimensional/multidimensional chromatography or heart-cutting methods, which are complicated to operate and high equipment costs. It is difficult for general enterprises to configure and cannot be popularized at all.

Tengzhou Haohan Chromatography Instrument Technology Service Co., Ltd. is advancing with the times, guided by the concept of scientific development, under the leadership of manager Wang Xiaoying, relying on Xiangying Institute of Analytical Technology, Chromatography Engineering Institute, Analysis and Testing Center, 3 scientific research The unit has developed the "Special Capillary Column for Purity Determination of MTBE Methyl Tertiary Butyl Ether", which has good repeatability and high accuracy, its relative standard deviation is less than 3%, and the relative error of each component is less than ±1%, which can meet the control of MTBE device Analysis and MTBE analysis of finished products. This method can be used to determine the purity of industrial methyl tert-butyl ether (MTBE) and the content of hydrocarbon impurities (greater than 0.005%).

MTBE methyl tert-butyl ether purity determination special capillary column determination spectrum: